In the fast-evolving world of electronics manufacturing, rigid flex PCBs have become essential for creating compact, lightweight, and durable electronic products. As we move through 2025, every rigid flex PCB supplier is racing to innovate integrating automation, AI, and sustainability into production.

This blog explores how leading rigid flex PCB suppliers are innovating in 2025, what trends are shaping the industry, and how these developments benefit OEMs (Original Equipment Manufacturers) and design engineers.

1. The Evolution of Rigid Flex PCBs

Before diving into innovations, it’s essential to understand the evolution of rigid flex PCBs.

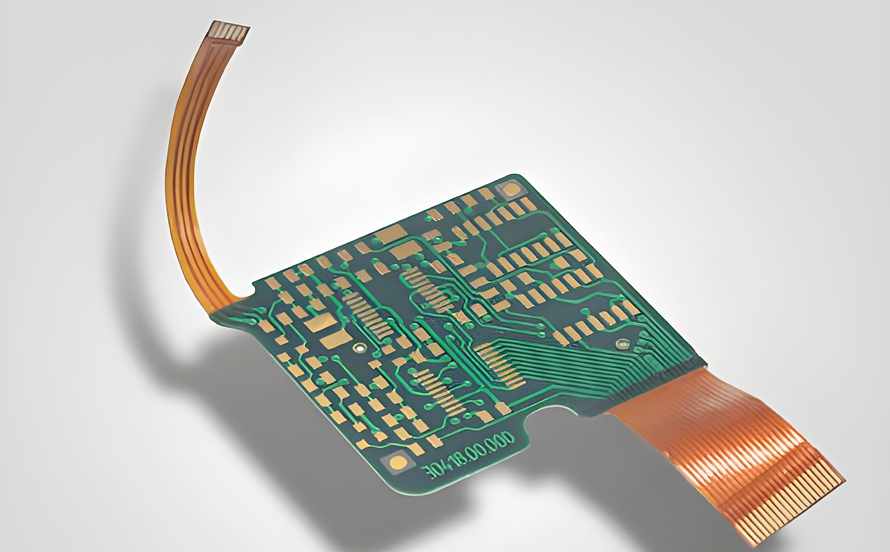

Traditionally, electronics relied on rigid PCBs or flexible circuits separately. Rigid flex technology merges the strengths of both offering the rigidity needed for structural support and the flexibility required for compact and movable designs.

Today, rigid flex PCBs are critical in aerospace, medical devices, wearables, automotive electronics, and military equipment, where space efficiency and reliability are paramount. As product designs become smaller and more complex, suppliers are investing in next-gen technologies to stay ahead.

2. Advanced Materials for Greater Performance

One of the biggest areas of innovation in 2025 is material science. Leading suppliers are adopting high-performance laminates and polyimide films that enhance flexibility, reduce signal loss, and improve thermal stability.

Key Material Innovations Include:

Low-Dk and Low-Df Materials: Reduce dielectric constant and dissipation factor, allowing faster signal transmission.

Halogen-Free Substrates: Environmentally friendly and compliant with RoHS and REACH regulations.

Ultra-Thin Copper Foils: Enable finer line widths and tighter spacing for compact, high-density designs.

High-Temperature-Resistant Adhesives: Support components that operate under extreme conditions.

By focusing on materials, rigid flex PCB suppliers are achieving higher signal integrity, reduced EMI (electromagnetic interference), and better durability — essential for next-generation devices.

3. Automation and AI in PCB Manufacturing

Automation isn’t new to PCB production, but in 2025, it’s taken a leap forward. AI-powered manufacturing systems are now standard among leading suppliers. These technologies streamline processes, reduce human error, and accelerate turnaround times.

How AI and Automation Are Transforming Production:

AI-Driven Design Verification: Automatically identifies potential design flaws before manufacturing.

Robotic Assembly Lines: Enhance precision in soldering and component placement.

Predictive Maintenance: Sensors monitor equipment health, preventing downtime.

Data Analytics for Yield Optimization: Machine learning algorithms analyze production data to improve quality and reduce defects.

This digital transformation enables suppliers to deliver consistent, high-quality PCBs at scale, ensuring reliability for demanding applications.

4. Sustainable Manufacturing Practices

Sustainability has become a priority in the electronics industry, and rigid flex PCB suppliers are no exception. With growing environmental regulations and customer expectations, leading manufacturers are embracing green initiatives.

Sustainable Practices in 2025 Include:

Eco-Friendly Etching and Plating Processes: Reduce chemical waste and water consumption.

Recyclable Materials: Use of halogen-free laminates and biodegradable packaging.

Energy-Efficient Equipment: Lower carbon footprint through renewable-powered facilities.

Zero-Waste Manufacturing Models: Reusing production scrap and minimizing raw material loss.

These initiatives not only reduce environmental impact but also enhance brand reputation and compliance with global sustainability standards.

5. Miniaturization and High-Density Interconnect (HDI) Capabilities

As electronics continue to shrink in size, miniaturization remains a top focus. In 2025, leading suppliers are developing HDI rigid flex PCBs with incredibly fine trace widths and microvias.

Benefits of HDI Rigid Flex Technology:

Higher Component Density: Enables more functionality in smaller devices.

Improved Electrical Performance: Shorter interconnects reduce signal delay and power loss.

Better Mechanical Reliability: Reduces stress points in dynamic flex areas.

This is especially valuable in medical implants, IoT devices, and aerospace systems, where space and performance are equally critical.

6. Advanced Testing and Quality Assurance

Quality control is crucial in PCB manufacturing, and suppliers are enhancing it with cutting-edge testing technologies. In 2025, innovations like 3D automated optical inspection (AOI) and X-ray analysis ensure that even microscopic defects are detected early.

Modern Testing Methods Include:

Automated Optical Inspection (AOI) with AI recognition.

X-Ray and CT Scanning for inner-layer defect detection.

Thermal Cycling and Reliability Testing for endurance assessment.

Electrical Testing with Flying Probe Systems for functional verification.

By integrating these advanced testing methods, suppliers guarantee higher yield rates and superior product reliability.

7. Global Collaboration and Supply Chain Innovation

The post-pandemic era emphasized the need for supply chain resilience, and leading rigid flex PCB suppliers are responding. Many now operate multi-regional manufacturing hubs to ensure timely delivery and cost efficiency.

Additionally, digital supply chain platforms are being adopted to improve transparency and collaboration. Customers can track production progress, quality reports, and shipment status in real-time enhancing trust and communication.

8. Customization and Rapid Prototyping Services

Modern clients demand flexibility and speed. To meet these needs, suppliers are offering on-demand prototyping, custom layer configurations, and quick-turn services.

Advantages of Rapid Prototyping:

Shorter Development Cycles: Accelerates time-to-market.

Cost Efficiency: Identifies design flaws early, reducing rework costs.

Design Flexibility: Supports complex geometries and hybrid assemblies.

These services help engineers iterate faster while maintaining high quality and precision.

9. The Future Outlook: What’s Next for 2026 and Beyond

Looking beyond 2025, the future of rigid flex PCB suppliers will likely involve further integration of AI, nanomaterials, and 3D printing technologies. As the demand for wearable tech, EVs, and autonomous systems grows, suppliers will continue pushing boundaries in flexibility, reliability, and sustainability.

The convergence of smart manufacturing, eco-innovation, and digital design marks a new era one where rigid flex PCB suppliers play a central role in advancing global electronics innovation.

Conclusion

Innovation in the rigid flex PCB industry is no longer just about producing high-quality boards it’s about creating smarter, greener, and more efficient manufacturing ecosystems. In 2025, leading suppliers are leveraging AI, advanced materials, automation, and sustainability to redefine industry standards.

For businesses and engineers seeking dependable partners, choosing a rigid flex PCB supplier that embraces these innovations ensures not only product excellence but also long-term competitiveness in the dynamic world of electronics manufacturing.

If you’re looking for a trusted and experienced partner for your next PCB project, visit Insight PCB, a leading rigid flex PCB supplier dedicated to delivering precision, quality, and innovation.

Write a comment ...